In this system, granular materials are conveyed using a close duct. There will be pipelines where the material is conveyed using a high-velocity stream or subjecting to the vacuum. The conveying system’s basic components include the blowing system, feeding system, pneumatic conveyor system, and cyclone separator.

Working principle of conveying system

Whenever we feed any granular materials on the feeder due to the air stream’s pressure, the weight of the materials will be lesser. The airstream pressure exerts so that the granules will be dispersed and travel through the conveying duct.

Types of pneumatic Conveying System

You can get three types of pneumatic conveying systems: vacuum or suction system, blowing or pressure system, and suck blow or combined push-pull system. In the pressure system, High pressure is supplied from the blower. Due to the high pressure, the particles will be conveyed through the conveying duct, and the granules will be separated in the separator. In the suction system, a blower system is present at the distance end. Due to the intense vacuum generation, granules will be conveyed through conveying pipe and separated in the separator. If still the granules are carried in Airstream, the granules are separated in a cyclone separator.

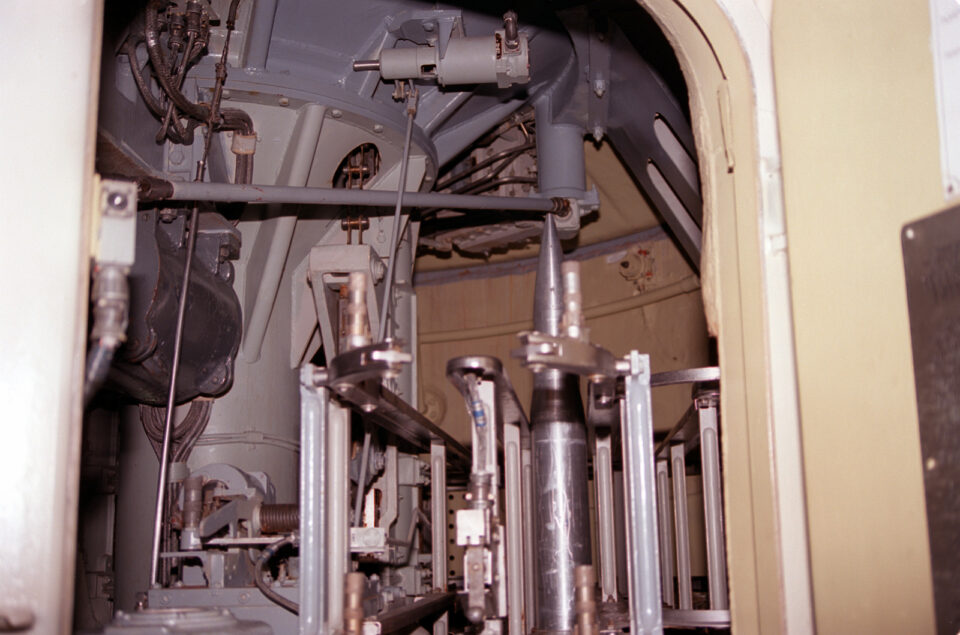

Before incorporating the grains into the conveying duct, the inflate materials disperse uniform quantity should be incorporated into the duct in the feeding system. There are several feeders, but the rotary feeder is very popular in the feeding system. The rotary feeding system consists of blades with some rotor packets or gaps. The material or granules, if filled in the rotor, then a fixed amount of granules will be filled in the pockets. Whenever the blade rotates, the granules will be incorporated into conveying duct.

There is another advantage of using conveying duct there are rotary lock facilities. So using this design, there will be no loss of Airstream coming from the left side of the pneumatic conveyor, and high pressure is given to this site. If the feeder doesn’t have a design, then there will be a back flow of the air stream through the feeding system. Which will not allow high-pressure Airstream to go back, due to which it will only travel through the conveyor duct.

Metering of feed is also available, predicting how much feed is incorporated or released through conveyor duct using this rotary feeder system. After feeding the material, it is conveyed through conveying duct, and the feed should be received at the discharge end.